Structural analysis is aimed at evaluating the strength of the components being studied.

Its use allows to avoid possible issues with regulations’ compliance and optimise component performance. It follows that structural analyses may be used during design- in order to achieve higher quality standards- or at a later stage, following manufacture, to identify and solve problems which may have arisen.

This type of analysis usually entails the use of 3D CAD modeling.

Kinematic Analysis

Any kind of pre-emptive analysis, although generally perceived initially as a simple cost addition, offers undeniable benefits. First of all a significant cost saving in terms of reducing the number prototypes manufactured and quantity of materials used. Because of this we offer a kinematic analysis to evaluate qualitatively and quantitatively the motion of a system, through the use of CAD software and spreadsheets. More specifically we evaluate the feasibility and design of mechanisms, clashes between parts during operation, position, speed and acceleration diagrams, as well as variations of forces during motion, contact analyses and much more. The aim being always that of optimizing every aspect of the subsequent manufacturing processes.

Structural Analysis

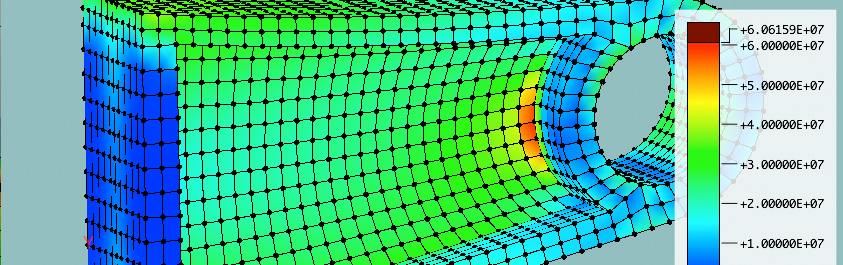

The purpose of Structural analysis is to study the behaviour of a component in its intended functional environment, and subjected to its working forces and thermal exposure; for example deformations stress, fatigue life, vibrations modes etc.

The analyses are performed using hand calculations, dedicated spreadsheets and full FEA software. This type of service is particularly important for the client as it allows to evaluate pre-emptively, during the design phase, suitable materials and their quantity, defining where they are to be used and therefore avoiding wasting expensive materials where they are not required and avoid making the part larger than required (less material used).

The first benefit offered by these studies is the reduction in number of prototypes required towards the definition of the final component, improving cost effectiveness. Structural analyses are also used after the design stage , on existing components, to evaluate possible improvements and define their magnitude.